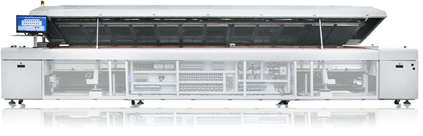

HTS series Reflow Oven is HT latest products.Which Developed 5 years ago and installed 3500+ worldwide. Its Proved high reliabilities and created reputation in specially high volume & loading production of 24 hours per day & 7 days per week environment.

+ Global support, Long warranty for heaters & blowers

+ 1st choice equipment provider for mobile phone industries

+ Worldwide proven excellent performance in Top 5 EMS Company

- Advantages:

- Low cost of ownership

- Long Warranty for Heaters & Blowers

- Excellent & Stable Performance

- Flexible Processes Control

- Lower Power Consumption& Oven surface temp.

- High efficiency heat transfer get minimal Delta T

Standard features

+ Intuitive GUI interface

+ PC with Windows 7

+Automatic Power On/Off (Auto timer)

+Data logging

+PCB Counter

+UPS System

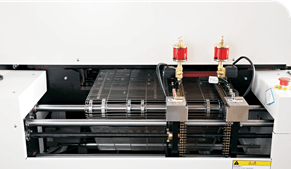

+Automatic Chain lubrication Systems

+Motoraized conveyor width adjustments

+ Rails +Mesh belts

+Double pin Chains Conveyors for extra protection

+Flux Management Systems (N2 Oven)

+Water Chiller (N2 Ovens)

+SMEMA Interface

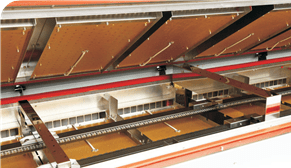

• Independent air velocity section control (Ramp-up, Soaking, Reflow) |

• Conveyor speed: 300-2000mm/min (12”-118”/min) |

• PCB edge clearance: 5mm (.196”) |

• PCB Max weight: 5 Kg (11 lbs.) |

• Conveyor height: 900 mm or 950mm +/- 20mm (37.4” +/- .78”) |

• PCB size: 50mm to 460mm (2” to 18”) |

• Optional 610mm (2” to 24”) |

• Component clearance top/bottom: 25mm (1”) |

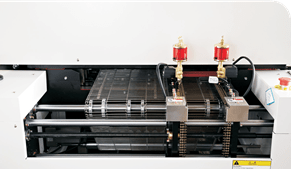

MODEL | HTS-0802/HTS-0802-N | HTS-1002/HTS-1002-N |

ELECTRICAL SPECIFICATIONS | ||

ELECTRIC SUPPLY | 3 PHASE, 380V 50/60Hz | |

TOTAL POWER | 64KW/67KW | 80KW/83KW |

STARTING POWER | Approx. 28KW/30KW | Approx. 32KW/34KW |

NORMAL POWER CONSUMPTION | Approx. 10KW/12KW | Approx. 13KW/15KW |

WARMING TIME | Approx. 25minute | Approx. 35minute |

DATA STORAGE | PROCESS DATA AND STATUS STORAGE (80GB) | |

ABNORMAL ALARM | ABNORMAL TEMPERATURE(EXTRA HIGH/LOW TEMP) | |

BOARD DROP ALARM | TOWER LIGHT: YELLOW-WARMING, GREEN-NORMAL, RED-ABNORMAL | |

Wave Soldering Machine: Make HT Electronics- Shenzhen

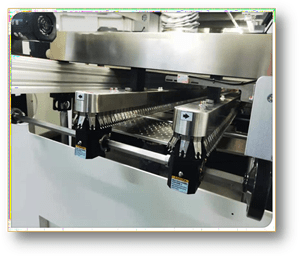

HTW-350/450 Wave HT Wave Soldering Machine HTW series are designed under the advanced concept with rich practice of lead free soldering processes.

HT Wave Soldering Machine HTW series focus on high stabilities,lower dross and modularized configuration for simple&easy maintanence.

HT Wave Soldering Machine HTW series’ performance were proved in many cusomters which was running high-volume manufacturing in 24 hours per day and 7 days per week.

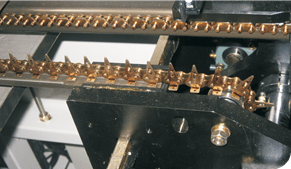

HTW Wave Soldering Machine standard equipped with V shape Titanium Fingers, option with Heavy duty Titanium fingers.

The standard V shape titanium fingers are suitable for PCBA without pallets or light pallets in thin edge, it shall work perfectly when the edge thickness

between 0.8mm to 2.6mm, meanwhile, the loading capacity is 25Kg

HTW-350/450 Features

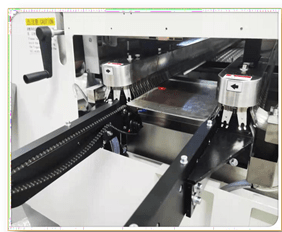

1、Conveyor system

2、Flux spray system

3、Preheating zones

4、Solder Pot

5、Cooling System

- Control System

MODEL | HTW-350 | HTW-450 |

GENERALSPECIFICATIONS:- | ||

DIMENSION(L*W *H) | 4160×1593×1735mm | 4160×1593×1735mm |

ELECTRIC SUPPLY | 3 PHASE , 380V/220V 50/60HZ | |

PCB Width Range (mm) | Min.80*60 – Max. 500*350 (L*W) | Min.80*60 – Max. 500*450 (L*W) |

PREHEATING MODE | BOTTOM:HOTAIRCONVECTION,TOPSIDE:IR | |

SOLDER POT CAPACITY | PB FREE : 500KG for Ceramic coating Pot PB Free: 550KG for Titanium Alloy Pot | |

EXHAUST VOLUME | 25M3/min. | |

COOLING | FORCED AIR (option: Industrial Chiller) | |