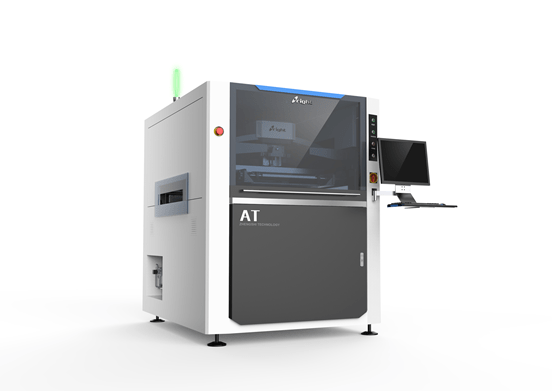

Rightprint International Limited was established in 2013 to manufacture the full automatic screen printers, who focus on designing and manufacturing the high precision screen printers for the SMT industries.

Our core R&D team has experience in the printers’ researching and designing over 10 years,we know the printing processes and customers’ need so that we can make the printer not only high precision and stabilities but also it is right printers for customers.The performance of our printers are proved by thousand customers, it combined our commitment to high performance and reliabilities with all necessary features for processing the more and more complicated PCB assemblies.

Our mission is to design and manufacture the higher precision and more stable printers to develop long terms partnership with our customers.

Belt conveyors.

– The conveyor speed is controlled by programmable motor and the PCB stop position is accurate. The flexible side clampping and vacuum support

System ensure the completely smooth contact between PCB & stencil.

User-friendly interface, intuitive operation come with navigation function.

The guidance is available for every operation step.

The printer designed with 3 types of under stencil cleaning: Dry, Wet and Vacuum, the 3 modes can independently selected or combi n e for use or manual cleaning if need.

The cleaning unit is separated from CCD camera, which can minimize the load to CCD unit for best accuracy on XY movement & extending the life. The sprinker system ensure the spray is uniform from top to bottom.

The arch bridge type of direct-connecting squeegee design can improve the stabilities and lifetime.

– Programmable floating print-head &self-adjustable

– Four sliders in two sides to ensure the accuracy and stablities of the squeegees movement.

– Two independent print-heads are driven by two high precision stepper motors with the closed loop pressure control system.

Specification

Model A6 AT L 8 | ||

Screen Frames | Min Size | 470X 37Omm 650X 650mm |

Max Size | 737X 737mm 8 50X850 mm | |

Thickness | 25 -40 mm 25 -40 mm | |

PCB Min Size | 50X50 mm 80X50 mm | |

PC B Max Size | 510X340 mm 510X5 1Omm 650X610mm | |

PCB T hicknes s | 04-6mm 0.2-6mm | |

PCB W arpage | X1% | |

Transport Height | 900*40mm | |

Trans port Direction | Left-R ight ;Right- Left;L eft-Left;R ight- Right | |

Transport speed | Max 150 0mm/S Programma bIe | |

Board Location | Support System | Magnetic Pin/Up—down table adjusted/supportblock by hand |

Clamping System | Side clamp ing,vacuum nozzle | |

Print head | Two indepen dent motorised printh e ads | |

Squeegee speed | 6-200mm/sec | |

Squ eegee Pres sure | 0- 15kg | |

Squeeg ee Angle | 60 /55 /45 | |

Squeegee Type | Stainlet s steel(Standard),plastic | |

Ste ncil Separati on Speed | 0.1-20mm/sec Programm abye | |

Cleaning Syste m | Dry.Wet.Vacuum(Programmable) | |

Ta bIe Adjustment ranges | X: z 1Omm;Y : z 1Omm; 8 : z 2 | |

Visio n System | Look Up/Down Optical Structure, CCD Came ra | |

Field Of Vision | 6.4”4.8mm | |

Solder Paste Inspectio n | 2D Inspection | |

Repeat Position Accuracy | *0.01mm -c 0.007mm z 0.01mm | |

Printing Accuracy | f0.025mm z 0.015mm I 0.025mm | |

Cycl e Time | ¥7s(Exdude Pnntng & Ck•aning) X8s(Exdude Pnrltng & Cleaning) ¢11s(Exclude Penting&Cleaning) | |

Product Chan geover | X 5Min | |

Air Required | 4.5-6 kg/cm‘ | |

Power Input | AC:220 10%,50/60HZ 1$ 3 MW | |

C ontrol Method | PC C ontrol | |

Machine Dimen sio ns | 1220(L)X1355(W)X1500(H)mm 1220(L)X1530(W)X1500(H)mm 1330(L)X1530(W)X1500(H)mm | |

Machine Weight | Approx: 1000kg Approx: 1200kg Approx:1200kg | |

| ||

A5 A8 | ||||

Sten cil Frames | Min.Size(X”Y) | 470”370 mm | 737”300 mm | |

Ma x.Size (X” Y) | 737”737mm | 1500“750mm | ||

Thicknes s | 25—40mm | |||

PCB Min. Size(X*Y) | 50”50 mm | 80*50mm | ||

PCB Max.Size(X”Y) | 400*340mm (Option:51 0*340 mm) | 1200” 350 mm | ||

PCB Thickness (mm) | 0.4—6.0 mm | |||

PCB W arpage | 1% | |||

Transport Height(mm) | 900+/—40 mm | |||

Transport Direction | L- R,R – L,L- L,R – R | |||

Trans port Speed (mm/s) | Max.1500.Programma ble | |||

PCB Positio ning | Support Meth od | Magnetic Pin,Auto U p-down Table & Suppo rt block | ||

CIamping Method | Side clamping, Vacuum n ozzles | |||

Print Head | Two independent m otor ized print h eads | |||

Squ eegee Speed | 6—200 mm/s | |||

Squeeg ee Pressure | 0 —15kg(Program co ntroI) | |||

Squeege e An gle | 6 0 /55 /45 | |||

Squeegee Type | Stainless Steel or Plastic | |||

Sten cil Separatio n Speed | 0.1—20 mm/s Programmab Ie | |||

Cleaning Method | Dry, wet,Va cuum(Prog ramma bIe) | |||

TabIe Adjustment Rang e | X :*—10 mm;Y:+ — 10mm; e : +—2 | |||

Vision System | Loo k Up/Down Optical Structure,CCD C am era | |||

Field Of Vision | 6.4”4.8mm | |||

Solder Paste Inspection | 2D Inspection | |||

Repeat Po sitioning Accuracy | +-0.01mm | +-0.008mm | +-0.01Smm | |

Print ing Accuracy | * —0.025mm | +—0.002mm | +—0.03 mm | |

cycle Time | 7s (Exclude printing&clean ing time) | <15s | ||

Product Chan geove r | <5min. | |||

Air Suppl y | 4.5-6Kg/cm2 | |||

Power Supply | 1Ph ase 220 VAC,50/60Hz 3KW | |||

Control Method | PC Control | |||

Dimensions(L”W“H) | 1220“ 135 5”1500(mm) | 2200*1200*1500(mm) | ||

Weight | Approx:1000Kg | App rox:1500Kg | ||